Technology

High

Frequency Welding

High

frequency welding method is usually often applied whenever

PVC

and PU products have to be welded.

Common

products manufactured with HF welding method are

stationery,

toys, packing, tents, pool, automobile parts, shoes,

medical

products, etc.

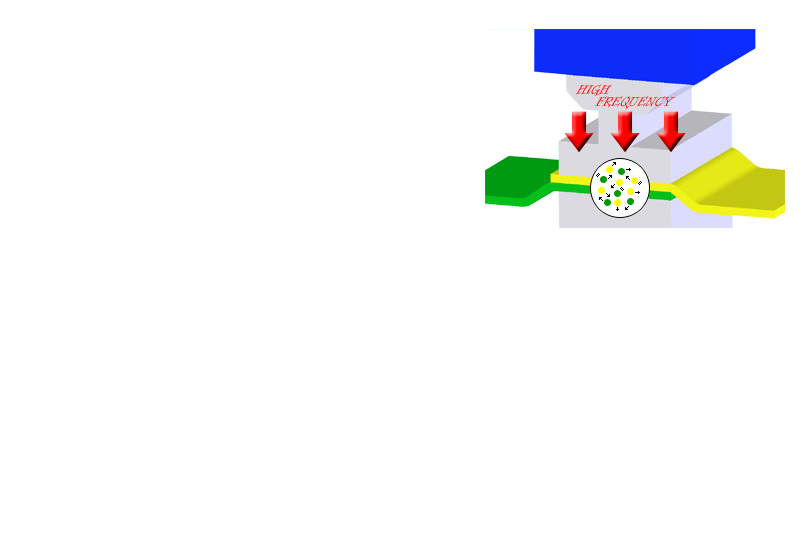

Principle

and advantages

The

main principle of high frequency welding is based on dielectric heating

of the material to be welded.

The

sheets of material are put between two metal plates (the electrodes),

whereupon a high frequency

voltage

is connected to the plates.

As

a result, the molecules in the material start vibrating, which results

in heating up

to

the melting (fusing) temperature.

By

bringing two layers of material into the HF field at the same time and

pressing them together,

the

layers melt together and form a strong welded joint.

The

great advantage of HF welding is the speed of welding

In

comparison with high frequency, in all other kinds of welding methods

(with

filaments, hot air or infrared radiation) the heat has to be added from

the outside.

It means the heat must first penetrate the material in order to make it

plastic enough to form a weld.

Copyright

@ 2012 SEWOO All Rights Reserved

Head

office & Factory

88-3,

Jangjincheon-gil, Ilsandong-gu, Goyang-si, Gyeonggi-do, Korea

TEL

: +82-31-967-1544 FAX : +82-31-967-1543

wholly

responsible for overseas trade

TEL

: +82-31-976-6016

E-mail

sewoo@eng7.co.kr